Innovators at 2JCP, a company owned by the Jet 2 fund, have been awarded a contract to construct a unique cleantech facility

(Brno, January 30) Specializing in cleantech technologies, the engineering firm 2JCP, located in Račice near Štětí, has embarked on a project to develop modular equipment in collaboration with KEW Technology, with backing from the British government. This project follows their successful partnership with Siemens Energy on hydrogen electrolyzers. The advanced system they're developing can produce highly pure hydrogen, industrial hydrogen, and CO2 from synthetic gas generated from waste or biomass. The construction of the inaugural pilot facility in Račice is scheduled to begin later this year, positioning 2JCP at the forefront of technology with vast potential for industrial applications in the green energy sector.

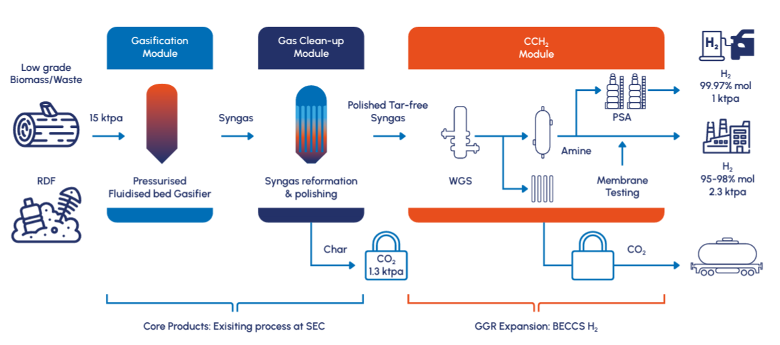

Last year, 2JCP emerged as a key supplier of industrial hydrogen electrolysers to Siemens Energy in Germany. The company has been involved in several projects, including underwater CO2 storage solutions in Norway, supplying components for offshore wind farms near New York, and constructing circular power plants for IKEA. At the start of this year, they secured a new contract with KEW Technology to engineer and produce a novel CCH₂ (Carbon Capture and Hydrogen Purification) device. This device represents a significant advancement in circular economy technology, capable of efficiently converting synthetic gas from waste or biomass into highly pure hydrogen, industrial hydrogen, and CO2.

Jan Pačes, business director and founder of 2JCP, notes, "Our potential clients include biomass processors, mixed waste handlers, and biogas station operators. The CCH₂ device produces emission-free hydrogen and carbon dioxide from synthetic gas generated during gasification for further industrial utilization." The exceptionally clean hydrogen produced can be used in fuel cells, while the captured carbon dioxide can serve in e-fuel production. Viewing carbon dioxide as a marketable product, generated more efficiently than traditional air or emission capture methods, marks an innovative step in contemporary energy practices.

The underlying technology, devised by KEW Technology in the UK, employs a process of water reduction using carbonaceous feedstock. 2JCP is currently finalizing the project design, with engineering to precede the production of the pilot device in the second and third quarters of this year. Following the pilot's completion, KEW Technology aims to start commercial production, potentially leading to 2JCP manufacturing modular CCH₂ devices for the global market. "Our extensive experience in modularizing large machinery, such as electrolyzers for Siemens Energy, positions us well for this project," states Vojtěch Křenovský, CEO of the 2JCP group. This partnership could yield annual revenues in the hundreds of millions of crowns for 2JCP.

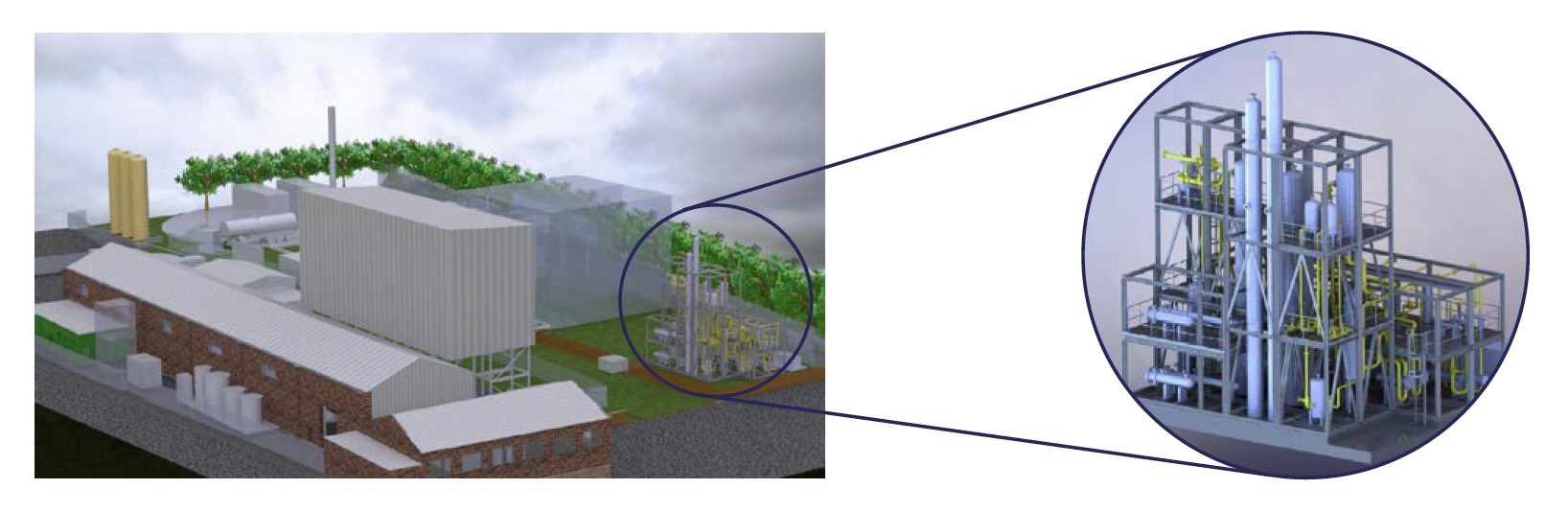

"The energy transition is undeniable, and at 2JCP, we are fully committed to it. We've identified four key areas in the new energy sector where we aim to make a significant impact: green hydrogen production, offshore wind parks, the circular economy, and carbon capture and storage," Vojtěch Křenovský asserts. The pilot device for the KEW Sustainable Energy Center in Birmingham is a testament to 2JCP's innovative approach, which intersects three priority areas.

The process performed by the new CCH₂ device from 2JCP is highlighted in orange (visualization source: KEW Technology)

Visualization of the CCH2 module and its integration into the KEW Sustainable Energy Center (visualization source: KEW Technology).